- Home

- About Us

- Product Categories

- Products Application

- Services

- Catalogues

- Blog

- Contact Us

- Gallery

- Videos

PROFILE LIGHTS TO BRIGHTEN

HISTORY ESPECIALLY

THE TIMES OF LIGHTS

After the industries revolutionized the art of working in early 18th century, the job of maintaining huge complicated machines soon became difficult. These machines would break down frequently and in many cases were not as efficient as the designers claimed them to be. With frequent efforts by scientists and engineers to ‘find more’ to ‘make more’, this feebly visible demand for shorter and easy-to-use machines became voiced out loud throughout the world. Such demands drove the world towards the dawn of a new era where tiny machines performed complicated tasks. This growth in technology simultaneously watered the ground for every other field of production to catch up to the current level of this evolutionary piece of work.

Semantically, Lighting techniques and other light related technology also made themselves competent like every other industry, to make their own place; in the modern electronically driven world. Soon these new lighting devices were incorporated to light big commercial spaces, developing corporate offices, being installed in small cabins of maglevs and bullet trains, and so on. Profile lights belong to one of those new revolutionary lighting technologies which were formulated in the 20th century under the concept of modern architecture, another arena of our world which levelled itself up with the growing era.

So, from the invention of tungsten filament bulb, later innovation was done for a better light production forming Mercury infused Gas Bulbs containing mercury deposits on both the electrodes. Frequent black deposits on the glass walls of the halogen bulbs indicated a very little life of incandescent bulb.

To make the bulb last longer, metal vapors were filled inside the glass lamp. Yet, the results were not satisfactory. Soon halogen gases replaced metal vapors to slow down the deposition of the vaporized tungsten on the glass walls of the bulb. But, due to the hazardous nature of mercury vapor to people in general; new alternatives had to be quickly found.

Phosphor coated halogen lights known as Florescent lamps were quickly commercialized due to robust performance but they always required a ballast, a device to kickstart the lighting device and also control the current flow. Contrarywise, these CFL lamps had several complications resulting from the electronic ballasts used. Not all the bulbs were satisfactory in their performance and had the danger of being blasted when encountered with even a drop of water. Such lights could be dangerous when used in bathrooms and for other water work related industries requiring a powerful lighting device.

Along with invention of CFL bulbs another invention almost had been simultaneously created over a period of time. Those were the Electronics Display screens which could project the light created on a tough glass panel to convey some form of information. These devices had a monitor which contained a thin film of phosphor coating later thickened for better reasons of clarity and robust lumen output. The core outline was to use the indigenous idea to excite electrons to transition from lower energy levels to higher energy levels and vice versa, thus forcing out the emission of resultant energy in the form of light. In the case of electronic display devices, these electron transitions were forced between two conducting strips physically separated by an air gap.

The idea of electron transitions to create light soon led the scientists to conduct several rigorous researches and a series of diverse experimentations to further use this principle to create another lighting device which could be smaller, thinner and better. Accordingly, the ‘alternate’ which the engineers were looking since centuries was said to be found. It was the LED light which was claimed to be ‘the’ alternate which could replace the gaseous CFL bulb and other older versions lighting bulb not to forget thick-walled display screens.

This LED light can be used to create any kind of lighting device of any kind of size and shape accompanied with an assurance of it being harmless to it’s environment. It can be fabricated as a miniscule chip in the size of millimeters or made as an individual low powered tiny bulb. Thus at pace with the race in technology, LED lights were introduced which now are widely used.

Profile lights, the new seasoned LED lighting devices are also basically a result of integration of this nascent digital technology, physics and semiconductor theory.

Recent Posts

-

Enhancing Architectural Beauty with Facade Lighting: The Ultimate Guide

-

innovative lighting solution 3in1 COB Downlights

-

lighting experience with 3 in1 Slim Panels

-

Affordable-3in1-spot-lights-the-ultimate-lighting-solution-for-any-room

-

Enhancing Your Indoor Spaces with Surface Panels

-

Using Profile Strips for Creative Lighting Design

-

Designing Your Space with Pendant Lights: Tips and Ideas

FEATURE PRESENTATION

PROFILE LIGHTS IN STRIPS

WHAT IS A PROFILE LIGHT?

A profile light is a modern LED Lighting device built to illuminate unreachable corners and sides of walls; pouring a kind of authenticity to the room. It is often used in the interiors of the house or building.

This lighting device has a very thin width but an extremely long length with it’s end so structured so as to allow either of the ends to attach to another profile light of same dimensions. Hence several profile lights can be attached end to end to form a larger, unitary, composite lighting device. This is especially helpful to create several possible arrangements made from several identical profile lights in efforts to build a uniquely patterned device.

Apart from styling the formed profile lighting device, the profile lights can be installed in any manner along the surface of the wall and in many cases are also pressed through the skin of wall to be embedded on the wall .

The objective behind the creation of this lighting device lies in the uniform directivity of the light emanated from lighting source. The light beam is specifically focused in one direction but also fabricated such that the luminescence of the light beam is just enough to softly highlight the corners and dark sides of wall.

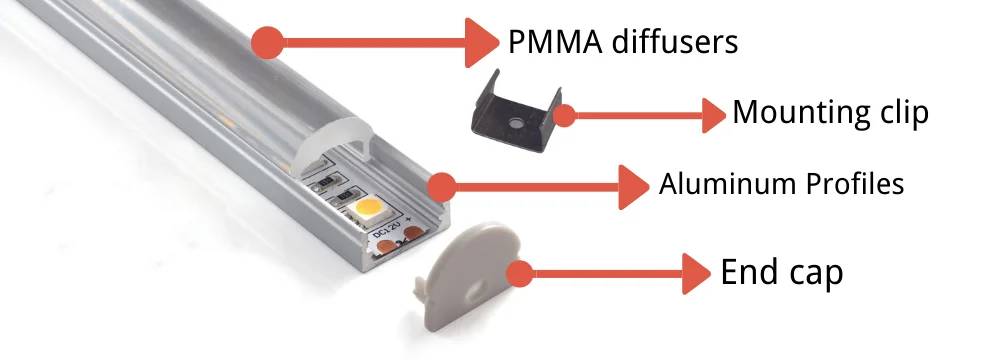

DIFFERENT COMPONENTS OF A PROFILE LIGHT

A Profile light is made up of several individual components attached together. These lights are exclusively used to light up those corners and edges of your walls and ceilings which are out of the reach of normal light bulbs to illuminate. As you might have noticed, profile lights are very thin, longitudinal structures which makes it even easier to slide upon the corners and edges. A read below shall let you know the components of the profile light.

PROFILE

Profile is a metal body which supports most of the constituents oriented in a particular direction to project the light in that directed angle. The LED strip light, main lighting component, is placed on it’s base known as a baseboard of the profile.

MOUNTING BOARD

The mounting board acts as an external support to be ‘the’ firm grip; holding the profile profusely on it’s place. It is tightly screwed to the wall at a defined place with electrical connections within the reach of the device. Mounting board is structured in different ways according to the type of profile used .

HEAT SINK

Despite the ability of metals to withstand increase in temperature, there is always a very frequently occurring probability that the metal can be damaged due to excessive thermal stress. To avoid this situation, an excellent thermal conductor or a heat sink is attached to be ‘the’ outlet to handle the job of directing thermal energy away from the lighting device. Especially in a profile light, a heat sink is a must since profiles are made of Aluminum, a metal; apart from the fact that the Lighting device also acting as a source of thermal energy is placed directly on the metal profile.

LED STRIP LIGHT

The LED strip light consists of several LED dies (small LED chips) arranged along a single line which are later embedded in the same arranged manner on the Metal PCB. These strip lights have their unique luminescence based upon the type of LED dies embedded on them. Note that different types of LED dies cannot be embedded upon the same strip.

DIFFUSER

An uneven distribution of light always occurs with LED dies. Not to forget the complicated semiconductor technology used to make those dies, most of them deliver light up to nearly 180 degrees from end to end. But we do not want that and neither do we want the case in which light emitted has too much glare which can damage our eyes. Acting as a preventive element, the diffuser does the work of shielding the extra UV radiations and excessive glare while making sure that there is no occurrence of an uneven distribution of light on the illuminated area. The diffuser is placed as a cap to cover the entire profile arrangement formed, provided that it is done before the now formed arrangement finally is attached to the mounting board.

PROFILE LIGHTS UNFOLDED

RECOMMENDED MATERIALS TO FORM THE 'PROFILE' OF THE LED PROFILE LIGHT

The profiles of the LED profile lights are mostly made up of pure Aluminum or an Alloy containing Aluminum. The Aluminum material used to make the profile must have a certain specified weight with a certain level of thermal capacity to effortlessly tolerate the heat generated by the LED light strip. As a precautionary measure, it is always recommended to once check the overall quality of the Aluminum metal used in making the profile with the main emphasis laid on it’s bulk weight. Copper also can be seen as an alternate material to aluminum. Considering the heat resistance as a performance measure, Copper stands as a very good thermal conductor. However, copper holds the disadvantage of being too heavy, bulky and expensive (not to forget the corrosion which it develops when exposed to air). Aluminum in the end has almost all the desirable qualities which surpasses copper making it the most preferable choice morphed into a profile.

How to make a profile light from a bunch of components ?

First, the profile is either materialized from the Aluminum metal by the manufacturer or directly procured from a well-established profile dealer.

The profiles of certain length, breadth and height are chosen according to the dimensions of the wall or ceiling.

Then the quantity of lumen output is calculated by using variety of light principles and related physics to give an approximate or the perfect magnitude of illumination desired by the consumer.

Also, these calculations help in deciding how many LED dies must be used to give that much amount of light and how long should the profile be given that the profile can sustain under the heat for a long period of time.

Accordingly, the suitable profiles are assembled and kept upon the mounting board. Then the continuous LED strip line is cut into smaller LED strips.

Each strip is epoxied to the metal body (profile) given that the heat sink is already attached to the profile before the epoxy.

Then electrical connections are attached to the profile device formed with one end closed with end cap (an outer covering to seal the end of the profile) and the other end is left open.

In case of multiple profiles, each profile is attached end to end with the help of connectors installed at each one end.

Finally, the diffuser is attached as the last step as a cap upon the profile to finally form a healthy functioning LED profile light.

TYPES OF PROFILE LIGHTS

SURFACE MOUNT PROFILE LIGHT

The mounting board is attached to the ceiling or on a shelf. The Profile arrangement containing both the aluminium profile and LED strip light is then inserted on the mounting board to form a surface mount profile light. This type of profile light is a lengthy strip with minimum width to spread light along it’s orientation on the wall / shelf.

RECESSED LED PROFILE LIGHTS

Recessed LED profile lights differ from ceiling light on the basis of structure and it’s installment. These lights are inserted into a well formed on the wall or ceiling having a considerable depth. The profile slips into the gap and seals itself to the well of the thick walled ceiling. Going a step above the profile upon the board lies the diffuser to eliminate the hotspots and other resultant illumination defects which always persist in any LED device as a principle defect.

CORNER PROFILE LIGHT

Being bent at an angle, the corner profile light slides to cover any cornered part of the room with curvilinear diffuser surface enclosing the strip light placed along the central axis for even distribution of light beam across all angles across the corner

SHELF LED PROFILE LIGHT

Shelf LED profile light has it’s own specifications distinguishing it as another different category of profile lights since it is exclusively designed for lighting thin slabs of glass or wood.

The mounting board has a unique structure which can support the profile when the arrangement so formed firmly grips one end of the slab. The LED strip light slides inside an empty slot provided by the profile with an opening to allow the light to spill over the edges of the slab.

COVE LIGHTING

Cove is a concept introduced in modern architecture which includes creation of a small extension below the ceiling with drywall having a satin finish for subtle effects. Cove lighting utilizes the concept of cove with the inclusion of LED light source on the cove to form soft illumination around the walls with no scintillations

GLO's CORNUCOPIA

WHEN PROFILE LIGHTS GAVE A 'GLO'

glo's Profile cove lighting series

- 17×8 mm

- Easy to install

- 2 years Warranty

GLO'S Profile linear lights series

- Panel is separate from the light and battery

- Higher wattages can be attained

- 2 year warranty

glo's Profile outdoor profile series

- Wiring can be eliminated

- Useful at remote areas

- 6 months warranty

glo's Profile outdoor profile series

- Wiring can be eliminated

- Useful at remote areas

- 6 months warranty

GLO's EDITORIAL CLIP (PAPER EDITION)

As we all struggle to sustain our lifestyle when high pricing is labelled on our daily needs almost every passing day, we often tend to seek a newer and cheaper alternative to replace our preferred choice of goods. And when we do so, it’s not very often that we use them. Lighting devices are needed the most in workplaces and in homes; enabling us to see in dark. In many ways, lights become a common source of accessibility to find the right resources available out of the dark. Yet, high pricing of much needed light devices has denied the opportunity of the those sections of middleclass economy who cannot afford expensive lighting devices to run their workshops given the amount of electricity they may use. In fact, many normal businessmen or brokers who have either established a small business or run rental workplaces cannot afford expensive lighting facilities provided by branded companies. The budget of what they can access lies in the local brands servicing feeble performance in spite of their pricing. Glo LED is co-founded by two individuals who have seen the struggle of a common man who cannot afford expensive lighting products required to run their homes, workshops, garages, warehouses, corporate buildings, mines, and so on. As a result their formed company GLO LED Pvt Ltd supply high quality LED lights in bulk at very low cost. The materials used are ISO 9001 certified which in itself indicates a very promising performance which every Glo LED product does live up to. To enhance the knowledge of anyone who tries to know about LED lights and how they work, Glo LED has launched free educative videos in YouTube for a sneak peek at what goes on to develop any lighting product. We have taken one more step forward to give access to knowledge through published informative blogs on our website which can help you to choose the best suited light accustomed to your needs.

With 535+ products and 5+ years of experience, Glo LED Pvt Ltd provides you Glo’s Catalogue for more product range in profile lightings.

Get Started Today

About Us

GLO LED Private Limited is a leading manufacturer and supplier of LED lighting solutions. GLO LED provides end-to-end solutions, from Consulting, Design, manufacturing, Supply, and Product Installation. The company has the expertise to deliver the orders to a wide range of industries

Social Media

Copyright © GLO LED Private Limited All Rights Reserved.

Design And Developed by RMR Web Tech