- Home

- About Us

- Product Categories

- Products Application

- Services

- Catalogues

- Blog

- Contact Us

POLES

originally engineered

WHAT ARE POLES MADE OF ?

A BEGINNER’S INTRODUCTION TO THE STREET LIGHT POLE

Street light poles are the hollow large tubular structure ranging between 3ft to 160ft, created with a sole purpose to be a perfect vertical support for the lighting device to be attached to. By the rule of thumb, it is a widely accepted fact that light has a broader spread when projected from a given vertical height. This engineered pole can actually hold the lighting device at large heights allowing a good amount of light to illuminate a given ground. The street light pole is manufactured and designed in several ways depending upon the material used. Surprisingly, there are different types of material, each one with endowed with it’s own unique properties.

STREET LIGHT POLES OUTLINED THROUGH AN ENGINEER’S PERSPECTIVE .. ...

A Street light pole basically supports a lighting device placed atop a polymethyl methacrylate plastic disk capped upon the top end of the pole. The material prevalent to build the pole include mild steel (a very basic form of carbon steel), and Aluminum alloy. Steel poles undergo corrosion very easily due to presence of iron metal substrate used whereas the aluminum poles are naturally anti-corrosive in nature. As a consequence, the steel poles are subjected to HDG (hot water galvanization) or cheaper form of galvanization called Cold Water Galvanization resulting in formation of Zinc Carbonate on the surface of steel. The Zinc carbonate coating forms a protective layer which prevents the material from rusting.

Every street light pole formed from either of these materials are welded with bottom flange plate being the metal base on which the pole is mounted upon. It is perpendicular to the large steel tube in orientation with small triangular metal pieces called as rib plates spot welded perpendicular to both the steel tube and the flange. The arrangement looks something like the one shown in the image at upper right part under this topic.

Recent Posts

-

Enhancing Architectural Beauty with Facade Lighting: The Ultimate Guide

-

innovative lighting solution 3in1 COB Downlights

-

lighting experience with 3 in1 Slim Panels

-

Affordable-3in1-spot-lights-the-ultimate-lighting-solution-for-any-room

-

Enhancing Your Indoor Spaces with Surface Panels

-

Using Profile Strips for Creative Lighting Design

-

Designing Your Space with Pendant Lights: Tips and Ideas

OLDIE’S POSTULATES TO MAKE A GOOD STREET LIGHT

The following postulates let you know the basic necessities required to build a street light pole. There’s a lot more physics involved in making a simple metal pole than might’ve thought of as you will see later in the blog.

- The street light must withstand sudden changes in wind pressure caused by frequent weather flips prevalent in the atmosphere given, at a certain height.

- The material of the pole should be rigid, anti-corrosive and resilient to extreme weather changes.

- The street light device must be mounted on either a suitable transparent plastic polymer or on a specific type of glass material to hold the reflected light beams. These are specifically used in LED Solar Street Light Poles.

- To minimize the loss of light which usually happens when the luminaires are not shielded properly, care must be taken to properly shield the luminaire.

- It is also required for the luminaire to be able produce considerable amount of light even after a period of time since most of these luminaires then produce lesser and lesser light as the time passes.

- Make sure to choose the best suited pole with accurate Effective Projected area measured with extreme precision by experts. The Effective Projected Area is the amount of force given by bulk weight of the luminaire and the craziest wind flow which the pole has to effortlessly survive through to stand unaffected in response to this force. If the Effective Projected Area of a pole is not enough to bear the force, the pole may collapse leading to severe damage to the lighting device and other components. So extreme care must be taken while measuring this parameter since any miscalculation will in many cases cost a loss of one complete street light including every component.

Design Specifications to engineer a pole

The following points outline the main designing perspectives one must take while making an efficient street light. Not digging deep into the technicalities and core light engineering principles, these points point out the key areas to look at while designing a street light pole.

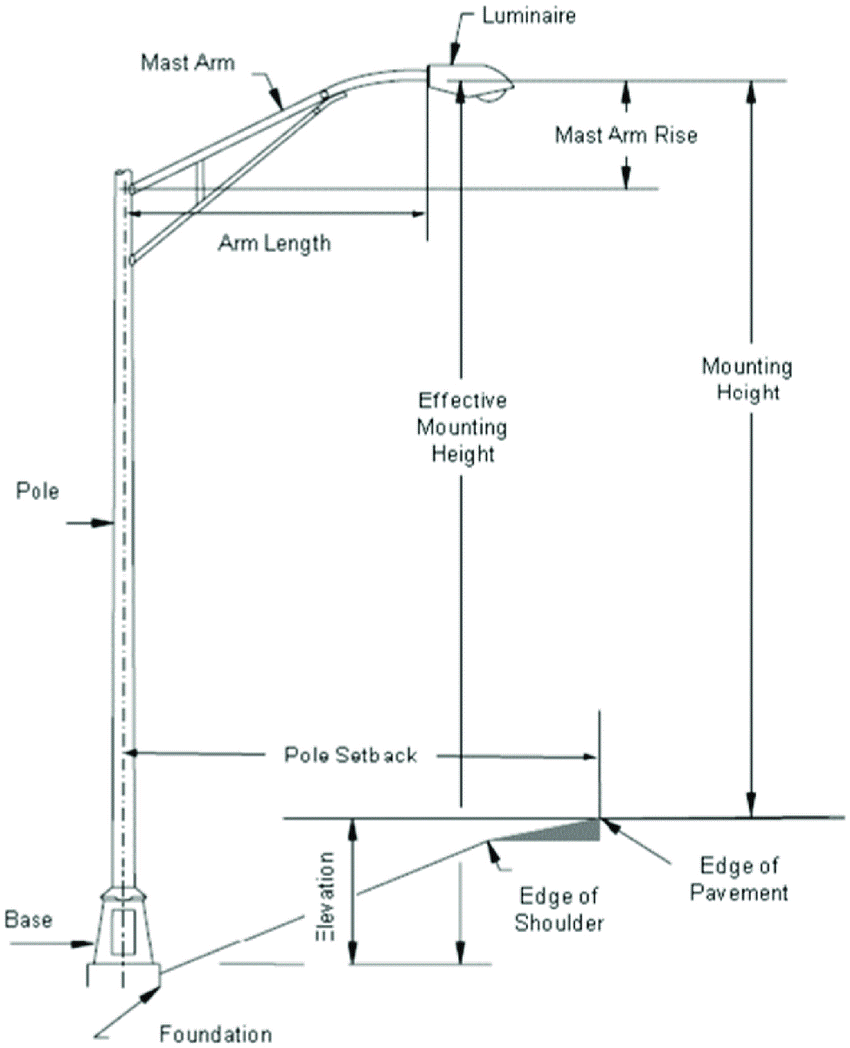

- The height of the street light pole from the mount formed to the center of the luminaire (lighting device) is called as ‘mounting height’. In simpler words, it’s the height of the street light from the mount, above the setback.

- The setback is the distance between the center of the base of the light pole to the extreme edge of the pavement. This distance when small provides better illumination while longer setbacks result in formation of hotspots on it’s edges. Although it is beneficiary to have a short setback, care must be taken that the light pole must not be installed way too near the extreme end of the pavement. The setback should be around the range of 3ft to 5ft in length.

- The overhang is the distance between the center of the luminaire to the line on the road where maximum traffic occurs . Make sure that the overhang does not exceed 1/4th of the total length of mounting height.

- Boom Tilt Angle or Boom Angle is the angle formed by the tilted beam of the light with respect to the imaginary horizontal line passing through center of the luminaire.

- The outreach is the distance between the center of the column and the center of the luminaire. This parameter is of much importance in field of architecture.

- Outreach parameter helps in giving additional polishing of illumination, infusing the lighting arrangement with a touch of austerity.

- Pole to pole spacing involves the distance between two adjacent poles. This parameter of spacing must be carefully calculated. The core field involved in determining pole to pole spacing is the fixture distribution.

- Fixture distribution is the pattern of the light beam formed based upon the orientation of two corresponding street lights either angled towards one another or placed on the same line. Also, individual beam pattern of each constituent Lighting device or luminaire also influences the fixture distribution.

EXTRA-CEPTS ABOUT METALS

WARP

Warp refers to the deformation of the shape of metal when exposed to extreme heat. It always is in the context of mechanical distortions caused particularly by thermal energy. Since, solar radiations also fall under the category of sources of thermal energy, warp becomes a common phenomenon in metals exposed to sunlight. So, the warp becomes a distinct parameter to segregate different metal materials which are used to make the street light pole.

RESONANCE

Resonance or in simpler words, Vibration in the metal commonly occurs in the metal street poles. Resonance or Metal vibration is further classified on the basis of strength of the produced.

FIRST ORDER RESONANCE:

• Includes vibrations of the pole on the top when hit by high velocity gusts of wind. These usually knock the top of the pole resulting in shorter and safer mode of vibrations called as first mode vibration

SECOND ORDER RESONANCE:

• Aeolian Vibrations or Second Mode Vibrations, prove strenuous to the brittle structure of the metal as they form along the mid-section of the pole. They are caused by low velocity, high frequency steady winds and due to pressure difference created between the wind facing side of the pole and the other side, vortices are created which then forces the mid-section to vibrate causing second order resonance.

• They have the ability to cause serious damage to a pole when prevailed for a long period of time

CHEAPER OR BETTER, WHICH METAL MATTERS?

Ever since the 19th century, there has always been a preferred notion to use Iron steel poles for constructing the street light. This old-fashioned anecdote is yet religiously followed by many manufacturers even at present. However, with the advent of new technology, cheaper and other easier materials are introduced to replace Iron steels. As we dive deeper into what makes a good street light pole, we shall also tap into other materials to know which is the best suited material to make your own streetlight.

GOOD OLD STEEL

Let us look at the outlines of pros and mostly cons of using steel as a building material for construction of a street light pole. These outlines will give a fair idea of what exactly are we looking for when we make a street light pole by using steel as an example.

STURDY STEEL SEALS THE DEAL

- The process involved to make a steel pole is easier than the ones needed for other materials like Aluminum. Steel pole production and manufacturing usually requires lesser capital than other metals, especially Aluminum

- The carbon steel, a form of iron steel is a bulky raw material with good amount of density packed in a single unit of measurement

- Steel is rigid in nature which results in fabrication of a sturdy, rigid pole with enough strength to last long especially in places with frequent weather changes. Once installed, it can last for 10-15 years.

- Carbon steel or mild steel is the best suited steel material for manufacturing street light. This steel is a solid solution with solvent being Iron and the solutes being Carbon which fill in the interstitial spaces (empty spaces of solid molecular structure steel) to make the steel stiffer and harder. Carbon can be added in various proportions to form various types of iron steel. Carbon steel or mild steel constitute of only 2% carbon while the remaining part is dominated by Iron.

HEAVY STEEL MAKES THEM KNEEL

- Steel being an alloy or a solid solution created by mixing molten forms of metal is very heavy. To mold the steel sheet to a hollow tube requires massive amount of mechanical energy to be applied externally. The rigidity of steel is a disturbing obstacle to overcome

- Due to the bulk weight of the steel, arrangement of proper transportation is problematic issue. As a consequence, the cost to avail proper transportation is high.

- The steel pole requires extra coating of anti-corrosive materials. Sometimes the pole may require multiple number of coatings to be resistant to corrosion.

ALUMINUM, A NEW ALTERNATE TO STEEL?

Let’s know Aluminum poles in a way such that it helps you decide when and where these poles should be used for.

EASY, FABRICABLE MATERIAL

- Aluminum is lightweight material which makes the job of transportation a bit easier.

- Not to forget the structure of the metal, Aluminum is very ductile and comparatively softer than steel. This property of Aluminum allows the manufacturer to shape it’s pole in any way with lesser external force applied.

- Aluminum metal is famous in the metal industries for it’s anti-corrosive property. Yes, Aluminum does not form rust when exposed to the air. This property saves the need to apply anti-corrosive coating reducing the cost.

AMENABLE TO TYPICAL WEATHER CAUSED TROUBLES

- Unfortunately, Aluminum has a structural property which makes the metal to frequent warps under the sunlight which can alter the shape of pole.

- Street light poles made of Aluminum easily develop fatigues (fractures formed in the metal) when exposed to harsh climatic conditions or extreme changes in weather. These fatigues are mostly formed as a result of resonance developed by the metal in response to the wind flow or the sun bath of the pole in the daytime.

- The joints must be welded with extreme care and precaution so that they do not develop cracks.

- Aluminum is a delicate material. The process of production of an Aluminum Street light pole is very complex. Likewise, this demands complicated machinery and various procurements. Together summed up, the cost of manufacturing an Aluminum pole from a plain aluminum sheet is actually very high, in fact, it is much higher than that of the steel pole.

FIBERGLASS: A BOON OR A BANE?

Fiber glass is made by throwing molten glass through holes in a rotating metal spinner. This forms extremely fine glass strands which are then mixed with polyester resin later woven into textiles to make the final thin ‘fibres’ called as the fibreglass.

FINER STRANDS TO ‘WRAP’ THE WEIGHT

- Fiberglass has the capability to withstand extreme load stress and has good insulation properties.

HOW MUCH DOES A WRAP CAUSE?

- Fiberglass requires an application of re-gel coating every five years of installation.

- Airborne fibers if formed can be detrimental to the respiratory health of asthmatic patients.

- Any gaps formed in the material to make the pole reduces it’s effectiveness.

HOW A METAL LIGHT POLE IS MADE AND WHAT ADDITIONAL COMPONENTS IT CONTAINS

Modern streetlights made with metals, especially steel are first transformed from a trapezoid shaped plane sheet to a hollow cylinder by application of tremendous force on the sheet to bend it to form the cylindrical shape. It’s similar to folding a plane sheet of paper along it’s central line with it’s risen sides curved by pressing simultaneously to form a cylinder. The curved sides of the metal sheet are welded together to form a closed cylinder. Later, the steel cylinder is symmetrically dented at both sides so that any expansion of the metal caused does not disturb the ability of the pole to withstand extreme loads or develop any faults. Also the these bent dents created helps the overall load to be distributed rather than being concentrated at one point. This gives the pole extra load bearing capacity. Then handhole holes are carved for manual fittings and ground lug attached for further connections. The hollow cylinder or metal pole is made. But, for a street light pole further engineering is required as illustrated below.

MY KIT OF ADDITIONAL YET COMPULSORY COMPONENTS

- If the material used is a metal for a street light pole, be ensured of the formation of first order resonance or second order resonance. To counter this disturbing obstacle, a vibration dampener is recommended as the best possible preventive measure. This electronic device does the magic of reducing the resonances by a good amount.

- Certain hole are carved out from the skin of the pole to allow installation of electric wires, battery, and to weld brackets (which form the arms of the pole to support the LED Lighting device) and handhole cover plates (they are required to seal the opening for made for fitting the ground lug inside).

- Brackets are the arms of the pole which are welded on the specific openings carved on the pole. The positioning and size of these openings are already pre-planned by the designers who handle the job to design what should the pole be like.

- A pole cap is a necessity apart from it being a very simple part which we may overlook at times. When the top end of the street light pole is exposed to the environment, many atmospheric particles such as dust, debris, water droplets, etc enter the hollow space inside. Now, these particles can damage the electrical components present inside the pole. This forms a good reason for needing a good and sturdy pole cap capped upon the top end of the pole exposed to the everyday world.

- A base plate is fixed at the bottom of the pole as a firm base along the leveled ground upon which the pole is to be thrusted into.

- Rib plates or small pieces or metal are orient themselves in a direction which is perpendicular with respect to vertical pole and the base plate. In other words, these pieces are placed vertical to the base plate and oriented diagonally with respect to the vertical pole. These pieces help in reducing the formation of fatigue

…

FAQs REGARDING GLO LED

HOW CAPABLE IS GLO LED?

GLO LED is ISO 9001 certified company which has several legal authentications licensed by latest government schemes. Our company has five years of rigorous experience in manufacturing poles, including every kind of LED Lighting device which can suit your needs.

GLO LED boasts 350+ high quality LED Lighting devices and different kinds of poles, hi-masts, bollards, solar lighting devices, and much more at a subsidized rate

WHAT MEASURES DOES GLO LED TAKES TO MAKE YOUR ARENA GLO?

GLO LED’s products undergo rigorous quality-checking processes before it is dispatched to the consumers. Much obsessed with satisfaction of our customers, our products are quality-checked once again before finally installing them at the required site or arena. Any issues yet occurred can be rectified by active customer services panel always under the scrutiny of the authority. We value every customer’s participation to build our company’s policy to provide high quality products to every economic strata in India, allowing their arenas to ‘GLO’ .

WHAT MATTERS IN THE END IS SECURED AND SAFER SERVICES

Our website in every way is tamper-proof with no additional pop ups and loud advertising. No cookies are enforced and no subscriptions are required. This is done purposely by the company to respect every customer’s privacy they explore our website.

HERE’S A LIST OF GLO’S CATEGORIES OF POLES TO SUIT YOUR NEEDS

TUBULAR

- MS MATERIAL

- 3 STEP DESIGN

- 3M TO 7M HEIGHT RANGE

OCTAGONAL

- GI MATERIAL

- OCTAGON DESIGN

- 5M TO 11M HEIGHT RANGE

LAMP POSTS

- DECORATIVE MODELS

- CUSTOMIZABLE

- WIDER PRODUCT RANGE

Get Started Today

About Us

GLO LED Private Limited is a leading manufacturer and supplier of LED lighting solutions. GLO LED provides end-to-end solutions, from Consulting, Design, manufacturing, Supply, and Product Installation. The company has the expertise to deliver the orders to a wide range of industries

Social Media

Copyright © GLO LED Private Limited All Rights Reserved.

Design And Developed by RMR Web Tech